+86-0577-66009580

+86-0577-66009580

juntmotor@126.com

juntmotor@126.com

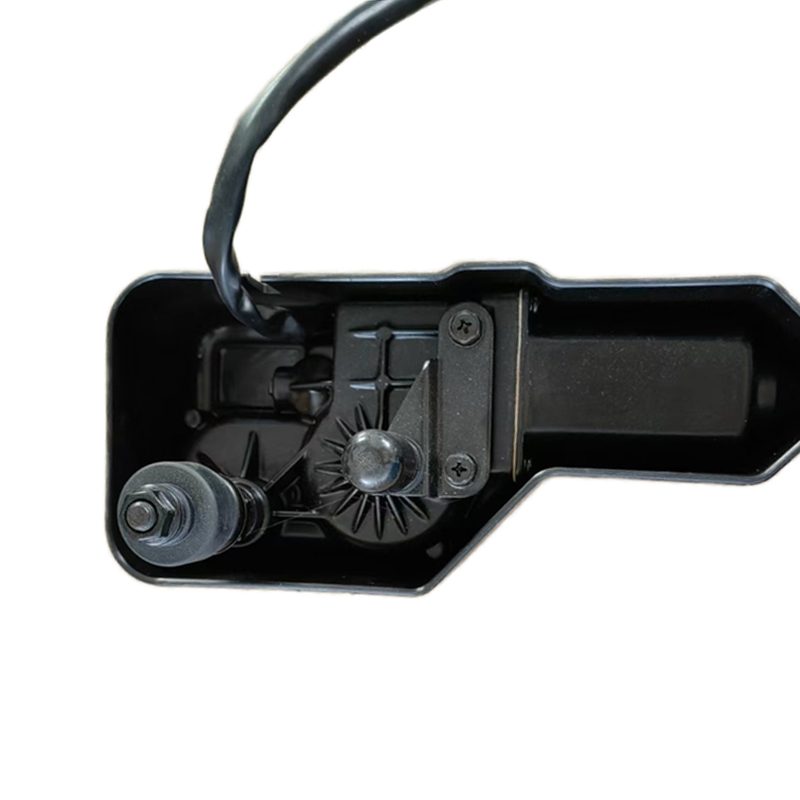

The 31641693014E motor is a versatile and reliable component used in various applications, including industrial machinery, automotive systems, and home appliances. Whether you are a technician, engineer, or someone looking to understand its features, this article will answer some of the most frequently asked questions about the 31641693014E motor.

The 31641693014E motor is known for its efficiency, durability, and performance. Some of its notable features include:

High Efficiency: This motor is designed to offer high energy efficiency, which is particularly beneficial for industries looking to reduce energy consumption and lower operating costs.

Durability: Built with high-quality materials, the 31641693014E motor is engineered to withstand harsh operating conditions, including high temperatures, humidity, and vibrations. This makes it a suitable choice for industrial and automotive use.

Versatility: The motor can be used in a wide range of applications, from powering machinery in factories to serving as an essential component in the automotive industry. Its adaptable design allows it to work in various environments.

Compact Size: Despite its powerful performance, the 31641693014E motor has a compact design that makes it easy to integrate into different systems and machinery.

Low Maintenance: One of the motor's standout qualities is its low maintenance requirements. This helps reduce downtime and ensures longer service life in demanding environments.

These features contribute to the motor's reliability and make it a preferred choice for both commercial and industrial purposes.

The 31641693014E motor is employed across a broad spectrum of industries due to its versatility and reliability. Some of the primary industries that benefit from its use include:

Automotive Industry: The motor is frequently used in automotive applications, particularly in electric vehicles (EVs), hybrid vehicles, and various automotive systems. Its efficiency helps reduce energy consumption and optimize performance in electric drive systems.

Manufacturing and Industrial Automation: In manufacturing plants, the 31641693014E motor powers various machines, including conveyor belts, robotic arms, and other automated systems. Its durability and performance in heavy-duty operations make it indispensable in these settings.

HVAC Systems: The motor is also commonly used in heating, ventilation, and air conditioning (HVAC) systems, where its reliability ensures smooth operation in both residential and commercial settings.

Agriculture: The motor is used in agricultural machinery like irrigation systems, harvesters, and other equipment, where its robustness helps in demanding, outdoor environments.

Home Appliances: Some home appliances, such as washing machines, refrigerators, and dryers, also feature the 31641693014E motor due to its compact design and efficiency.

Given its wide applicability, the 31641693014E motor plays a crucial role in ensuring smooth operations across multiple industries.

Proper maintenance of the 31641693014E motor ensures longevity and efficient operation, reducing the likelihood of unexpected failures and costly repairs. Here are some essential maintenance tips:

By following these steps, you can ensure that the 31641693014E motor continues to operate at peak performance for years.

Like any mechanical component, the 31641693014E motor will eventually show signs of wear and tear. Early detection of problems can help avoid more costly repairs or system failures. Here are some common indicators that the motor might need attention:

To ensure safe operation and long-term reliability, several precautions should be observed when installing, operating, and maintaining the 31641693014E Motor. Attention to these factors reduces the risk of premature wear, electrical faults, and unexpected downtime.

Installation practices are critical. The motor should be mounted on a flat, rigid surface to prevent misalignment and vibration. Improper mounting can lead to bearing stress and uneven shaft loading. Before connection, verify that the power supply voltage and frequency match the motor's rated specifications. Incorrect electrical parameters may result in overheating or unstable operation.

Electrical safety must be prioritized. All wiring should be performed by qualified personnel using appropriate protective equipment. Ensure that grounding is properly implemented to prevent electric shock and protect connected control systems. Terminal connections should be tightened to the specified torque to avoid arcing or intermittent contact. Protective devices such as circuit breakers or overload relays should be installed to safeguard against abnormal current conditions.

Thermal management requires continuous attention. Adequate ventilation around the motor housing is necessary to allow heat dissipation. Obstructed airflow or installation in confined spaces can raise operating temperatures and reduce insulation life. Periodic temperature checks during operation can help identify cooling issues before they escalate.

Operational loading should remain within rated limits. Avoid sustained operation beyond the specified torque or speed range. Excessive mechanical load can accelerate wear of the rotor, shaft, and bearings. When the motor is used in variable-load applications, appropriate control systems should be employed to smooth start-up and load transitions.

Maintenance and inspection routines should be established. Regularly inspect bearings for noise or vibration, check insulation resistance, and verify that fasteners remain secure. Lubrication, if applicable, should follow the manufacturer's recommended intervals and materials. Clean accumulated dust or debris from the housing to maintain cooling efficiency.

Environmental considerations should not be overlooked. The motor should be protected from corrosive atmospheres, excessive humidity, and contaminants that could penetrate the enclosure. If operation in challenging environments is unavoidable, additional protective measures such as sealed housings or external shields may be required.

By observing these precautions, users can ensure that the 31641693014E Motor operates safely, maintains consistent performance, and achieves its intended service life. Proper handling, correct installation, and disciplined maintenance together form the foundation for reliable motor operation in professional and industrial settings.