+86-0577-66009580

+86-0577-66009580

juntmotor@126.com

juntmotor@126.com

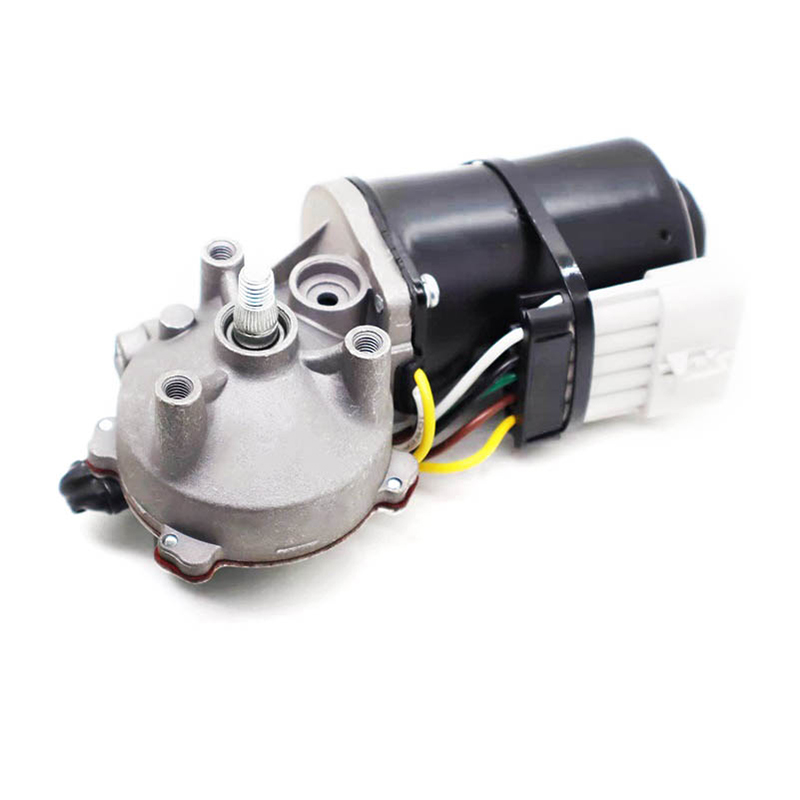

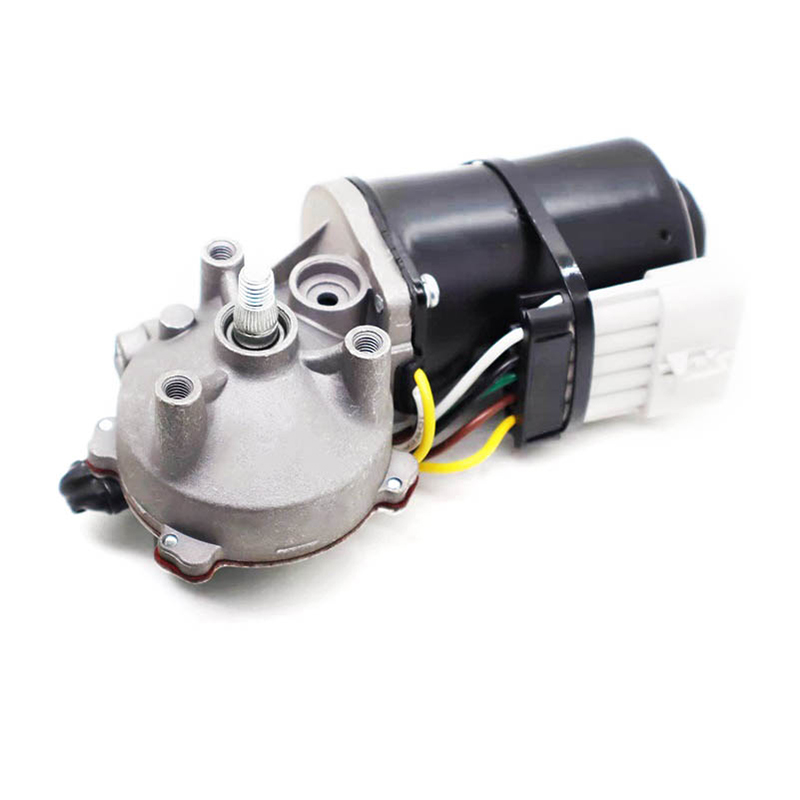

The 17258570 wiper motor is a model commonly referenced in the automotive aftermarket and original equipment replacement sector. It is typically used to drive windshield wiper systems in passenger vehicles, light trucks, or specialized equipment. Like automotive electric motors, its reliability depends heavily on material selection, structural design, and correct usage.

The 17258570 wiper motor is built from a combination of metallic and non-metallic materials, each chosen to meet specific electrical, mechanical, and environmental requirements. While exact formulations may vary slightly by manufacturer, the overall material structure follows standard automotive motor design principles.

Key material components typically include:

Motor housing:

The outer shell is usually made from cast aluminum or stamped steel. Aluminum is often preferred because it offers moderate strength, corrosion resistance, and low weight. Steel housings are sometimes used in cost-controlled designs and are usually treated with coatings for rust protection.

Armature and shaft:

The rotating shaft and armature core are generally manufactured from carbon steel or alloy steel. These materials provide the torsional strength required to drive the wiper linkage under varying loads.

Copper windings:

The internal coil windings are made from insulated copper wire. Copper is used for its stable electrical conductivity and predictable behavior under continuous current flow.

Permanent magnets or field coils:

Depending on the design type, the motor may use permanent ferrite magnets or electromagnetic field coils made from copper and silicon steel laminations.

Brushes and commutator:

Carbon-based brushes are used in contact with the copper commutator. These materials are selected to balance electrical performance with wear resistance.

Sealing components:

Rubber or synthetic polymer seals are used at shaft exits and housing joints to limit moisture and dust entry.

Together, these materials allow the 17258570 wiper motor to operate under vibration, temperature variation, and moderate moisture exposure typical of vehicle operating conditions.

Many automotive wiper motors, including the 17258570 type, incorporate a reduction gearbox. This gearbox converts high-speed motor rotation into low-speed, high-torque motion suitable for driving wiper arms through linkages.

The gearbox materials usually include:

Gear sets:

Gears are commonly made from engineered plastics such as nylon or acetal, or from sintered metal alloys. Plastic gears help reduce noise and vibration while lowering overall weight. Metal gears are favored for higher load tolerance.

Gearbox housing:

The gearbox cover is often part of the main motor housing or made from reinforced polymer. This helps protect internal components while maintaining dimensional stability.

Lubrication grease:

Specialized automotive grease is applied to reduce friction and wear. This grease must remain stable across a wide temperature range.

Bearings and bushings:

Bronze bushings or small steel ball bearings are used at load points to support rotating shafts and reduce friction.

The material pairing inside the gearbox is carefully selected to balance wear resistance, noise control, and service life. Inadequate material matching could early gear wear, increased noise, or intermittent wiper performance.

The 17258570 wiper motor is installed as part of the windshield wiper system and works in coordination with the wiper linkage, windshield washer system, and electrical controls.

In practical use, its operation follows a standard process:

This motor typically supports multiple operating modes, such as:

In some vehicle designs, the motor also integrates a position-sensing mechanism to ensure the wipers return to their resting position when turned off. This function relies on both electrical contacts and precise mechanical alignment within the motor assembly.

Although the 17258570 wiper motor is designed for long-term use, its performance and service life depend strongly on correct installation and reasonable operating conditions.

Installation Considerations

Incorrect installation can place extra load on the motor, reduced operating stability or premature electrical wear.

Usage Behavior

Under normal conditions, the motor is designed for frequent short-term operation rather than constant continuous duty. Good usage practice includes:

Maintenance Aspects

The wiper motor itself is usually a sealed unit and not intended for routine disassembly. However, related maintenance tasks can help preserve its function:

If the motor begins to show symptoms such as uneven speed, failure to park correctly, or intermittent stopping, electrical testing is often required to determine whether the issue lies in the motor, control switch, relay, or wiring.