+86-0577-66009580

+86-0577-66009580

juntmotor@126.com

juntmotor@126.com

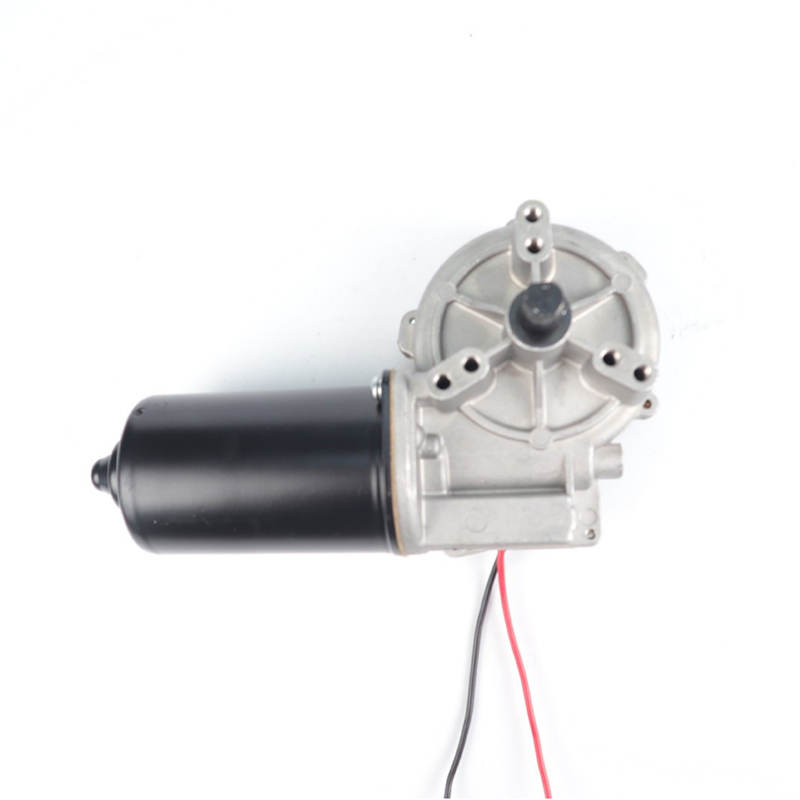

The quest for energy efficiency has become a top priority, as businesses and industries seek to reduce their carbon footprint and operational costs. One of the key technologies that have emerged as a game-changer in this pursuit is the gear reduction electric motor. These motors are designed to provide a significant reduction in speed while increasing torque, a crucial aspect for many mechanical applications.

Gear reduction electric motors are integral to numerous applications requiring high torque at lower speeds. These motors are not just about power; they are about optimizing energy usage. By incorporating a speed reducer motor into their systems, industries can achieve a precise control over the speed of their machinery, which directly translates to energy savings. The reduction in speed allows for a more controlled and efficient operation, minimizing energy waste and enhancing overall performance.

Parallel shaft helical gearmotors are a specific type of gear reduction electric motor that has gained popularity due to their efficiency and durability. These gearmotors feature a parallel shaft arrangement, which simplifies the integration into existing machinery. The helical gear design within these motor systems allows for a smooth and quiet operation, reducing wear and tear, and thus, reducing the need for frequent maintenance. This not only saves energy but also reduces downtime, which is a significant factor in maintaining operational efficiency.

The application of gear reduction electric motors can be found across various industries, from automotive to food processing. In the food processing industry, for instance, these motors are used in conveyor systems, where a speed reducer motor is essential for controlling the speed of the conveyor belt. This precise control not only ensures the quality of the product but also prevents overuse of energy, as the motor operates at efficient speed for the task at hand.

In the automotive industry, parallel shaft helical gearmotors are utilized in electric vehicles to control the speed of the vehicle. The gear reduction provided by these motors allows for the good use of battery power, translating to a longer driving range and reduced energy consumption. This is a prime example of how gear reduction electric motors contribute to the overall energy efficiency of the vehicle.

While energy efficiency is a primary concern, gear reduction electric motors offer additional benefits. These motors are known for their robust construction and long service life, which means less frequent replacements and lower maintenance costs. This, in turn, contributes to the overall efficiency of operations, as downtime due to motor failures is significantly reduced.

Moreover, the use of gear reduction electric motors in applications such as wind turbines and solar tracking systems allows for precise control over the direction and speed of the mechanisms. This precision is crucial for improving the capture of renewable energy, further emphasizing the role of these motors in the broader context of sustainable energy solutions.

The role of gear reduction electric motors in enhancing energy efficiency cannot be understated. From their ability to control speed and torque in various applications to their contribution to the longevity and reliability of machinery, these motors are a cornerstone of modern industrial operations. As industries continue to evolve and the demand for sustainable energy solutions grows, the importance of gear reduction electric motors, parallel shaft helical gearmotors, and their impact on energy efficiency will only become more pronounced.