+86-0577-66009580

+86-0577-66009580

juntmotor@126.com

juntmotor@126.com

The low speed gear motor has emerged as a critical component in applications requiring precise movement and gentle starting action. Unlike standard gear wala motor options, these specialized units offer unique advantages that make them indispensable in various sectors.

Understanding Low Speed Gear Motors

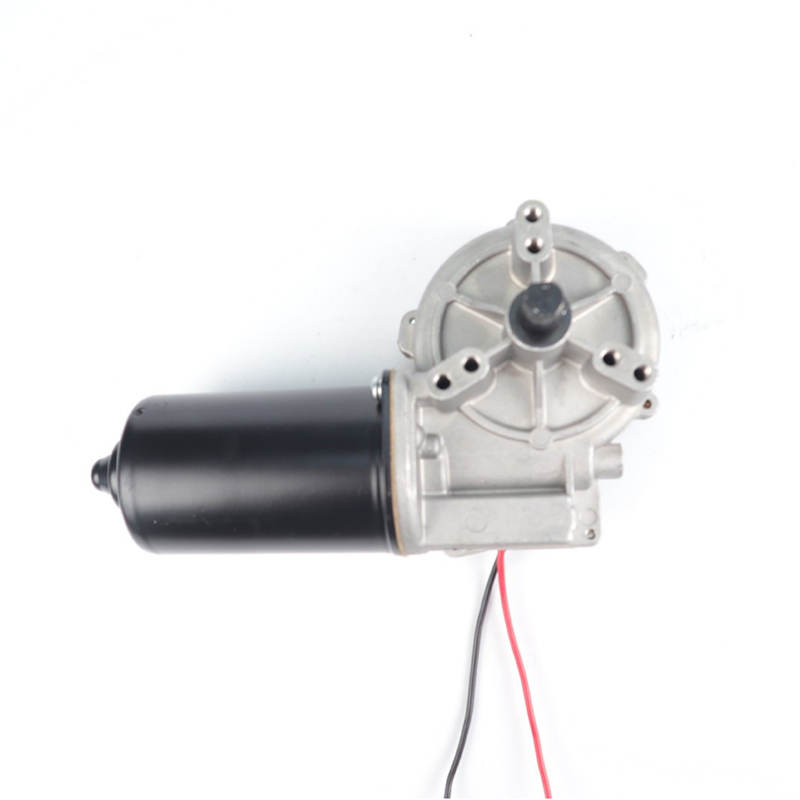

A low speed gear motor combines an electric motor with a gear reduction system to deliver good torque at reduced speeds. This differs significantly from conventional geared starter motor designs that prioritize quick acceleration. The beauty of these systems lies in their ability to provide controlled, stable motion - whether it's for conveyor systems in food processing plants or precision positioning in medical equipment.

One of the key advantages of a properly specified gear wala motor with low-speed capabilities is its inherent ability to eliminate the need for additional speed control mechanisms. This simplifies system design while improving reliability - factors that maintenance engineers particularly appreciate.

Applications Where Low Speed Matters

The low speed gear motor truly shines in applications where gentle starts are crucial. Consider automated gates in residential communities - a standard geared starter motor might jerk into action, creating safety concerns and mechanical stress. The slow, controlled acceleration of a properly engineered gear wala motor solves these problems elegantly.

Other prime applications include:

- Assembly line positioning systems

- Agricultural equipment requiring precise seed placement

- Packaging machinery with delicate product handling

- Solar tracker systems needing smooth movement

In these scenarios, the low speed gear motor provides the great balance of power and control that conventional geared starter motor options simply can't match.

Technical Advantages Over Standard Options

When comparing a gear wala motor designed for low-speed operation against traditional geared starter motor solutions, several technical benefits become apparent:

1. Reduced Mechanical Stress: The gradual acceleration minimizes wear on gears and bearings

2. Higher Starting Torque: Enables movement of heavy loads from standstill

3. Energy Efficiency: Eliminates the power spikes associated with standard starts

4. Precision Control: Delivers exact positioning without complex feedback systems

These characteristics make the low speed gear motor particularly valuable in applications where reliability and precision are paramount.

Cost Considerations and Long-Term Value

While the initial gear wala motor price point might be slightly higher than conventional geared starter motor options, the total cost of ownership often favors the low-speed solution. Reduced maintenance requirements, longer component life, and energy savings typically offset the initial investment within two years of operation.

For operations running multiple shifts or continuous processes, the low speed gear motor proves especially economical. The reduction in downtime alone can justify the upgrade from standard geared starter motor configurations in many industrial settings.

Future Trends in Motion Control

As industries continue to prioritize precision and energy efficiency, demand for specialized low speed gear motor solutions will only grow. Manufacturers are responding with increasingly compact designs that maintain high torque output while fitting into tighter spaces than traditional gear wala motor options.

The evolution of these motors is particularly exciting in the context of smart factories and Industry 4.0, where the integration potential of low speed gear motor units with digital control systems opens new possibilities for automated precision. While conventional geared starter motor products will maintain their place in certain applications, the future clearly belongs to intelligent, application-specific solutions like these optimized low-speed units.

For engineers and specifiers, the message is clear: when your application demands controlled motion and gentle operation, the low speed gear motor should be your first consideration. Its combination of performance, reliability, and long-term value makes it an increasingly smart choice across countless industrial and commercial applications.